For most of us, our boats will spend most of their lives on the trailer. Unfortunately, boat trailers tend to be one of those out-of-sight, out-of-mind things that don’t receive the attention they deserve until something breaks in the middle of nowhere.

For most of us, our boats will spend most of their lives on the trailer. Unfortunately, boat trailers tend to be one of those out-of-sight, out-of-mind things that don’t receive the attention they deserve until something breaks in the middle of nowhere.

Not to worry; we’re here to help with advice from boat trailer experts to assist you in keeping your boat trailer road-ready and safe for years to come.

Tires and Wheels

Don’t underestimate the importance of these two things. According to the RMA® (Rubber Manufacturing Association), the number one cause of tire failure is under inflation. Running a trailer tire at less than 80 percent of the recommended maximum inflation pressure can quickly inflict serious injury to the tire, because an under-inflated tire can’t carry as much weight as it could with the proper inflation pressure in it. Thus, an under-inflated tire works harder, generating tremendous heat, potentially leading to premature tire failure due to internal damage.

Rick Huddleston, Trailer Engineer for Ranger® Boats, was recently at a large fishing tournament where he personally checked the inflation pressure in the tires of over 400 Ranger® boat trailers. Eighty to ninety percent were under inflated, some were worn out and some were damaged; a frightening discovery, to say the least. The moral of the story: just about everyone, including avid anglers, can be guilty of neglecting their trailer tires.

Tire Tips:

• Use nitrogen if possible, rather than air, because nitrogen attracts less moisture.

• Use tires that are rated for trailer towing.

• Keep the inflation pressure at the maximum PSI recommended on the sidewall of the tire.

• Keep a cap on the valve stem to prevent contamination of the internal rubber valve.

• Always travel with a spare tire and check the spare tire’s inflation pressure along with the other tires.

• If you experience a blowout, slowly move over to the right off the road to change your tire and check the other tires for possible damage.

• Don’t overload the trailer tires. The maximum load is listed on the sidewall of your trailer tires.

• Give your trailer tires a visual check before each trip.

• Keep your trailer tires in a cool, dry place and out of direct sunlight during storage if possible.

• Replace your trailer tires in accordance with the manufacturer’s recommendation.

Another part to consider is the lug nuts. Many simply put the lug nuts on tight, and then forget about them. The problem is that lug nuts can work loose and fall off at the most inopportune times. If you’ve bought a new trailer (or boat and trailer package), the lug nuts need to be checked and re-tightened after only 100 miles.

A good way to ensure the lug nuts are properly tightened to the recommended torque (as specified in the trailer owner’s manual, using common sense and appropriate safety measures) is to follow this simple process:

• Remove the lug nuts.

• Using a high-quality torque wrench, and tighten the lug nuts to the appropriate torque value.

• Repeat at least twice a year.

• Check the lug nuts before each trip.

Hubs and Bearings

The trailer wheel and tire ride on a spindle on the end of the axle. Two sets of wheel bearings, an inner and an outer bearing, actually carry the load between the wheel and the spindle. Wheel bearings work hard, and it’s important to make sure the bearings always have sufficient lubrication. Therefore, it’s your job to check the wheel bearing grease/oil every time you leave the house with the boat trailer.

Wheel bearings get hot as you cruise down the road. These hot bearings then get dunked in the cool lake water when you launch the boat, creating somewhat of a vacuum in the bearing housing, literally forcing water into the wheel bearings. You can prevent bearing failure by making sure the wheel bearings are completely full of grease/oil, so there won’t be any space in the bearing housing for water.

Brakes

Many boat trailers are also equipped with a braking system. These can be electrically operated or the more popular surge type, which operate via a hydraulic surge coupler.

The hydraulic surge coupler is a master cylinder built into the trailer hitch coupler. This piece of equipment performs double duty: it attaches the boat trailer to the tow vehicle and operates the trailer brakes.

When the tow vehicle slows down, the boat and trailer want to keep on going. The energy of the trailer moving forward pushes a piston in the surge coupler’s master cylinder (similar to a driver using a car’s brake pedal). Hydraulic fluid in the master cylinder and the brake system is pressurized, activating the trailer brakes.

With either type of system, always make sure to follow the manufacturer’s maintenance and service recommendations. Also, every time you hitch up to the trailer, visually inspect the brake system for leaks, and check to make sure the brake lines aren’t rubbing against the trailer frame. Check the trailer’s brake fluid, too, and keep it topped off using the manufacturer’s recommended brake fluid.

Lights

Trailer lights can be one of the most frustrating items to fix. Tracking down an electrical problem in the dark isn’t easy, and that’s why we suggest checking the trailer lights (and resolving any issues) in the driveway at home, rather than by the side of the road.

Common trailer light issues/solutions include:

Issue: Debris in the trailer/tow vehicle plug-in connector

Solution: Blow/knock out the dirt or foreign objects.

Spray the connections with a water-displacing oil. Apply a small amount of dielectric grease in the plug can help prevent corrosion.

Issue: Poor ground connection

Solution: Check the white wire at the plug-in connector.

Make sure the white wire isn’t broken, loose, or rusty where wire fastens to trailer frame. Make sure to also check the white wire between the plug and your tow vehicle and clean the connection if necessary.

Issue: Non-functioning light(s)

Solution: Check the bulbs, replace as necessary. If the bulbs are OK, use a test light or multi-meter to verify that wiring is intact.

Bunks, Rollers, and Winches

Bunks and rollers support the boat for most of its life, so making these workhorses function properly should be a priority.

Bunk inspection:

• Make sure the carpet is intact with no tears or worn-out areas.

• Make sure the bunk is securely fastened; all the bolts must be tight.

Roller inspection:

• Make sure the rollers are in serviceable condition. There should be no cracks or other damage on the rollers and they must spin freely.

• Make sure the rollers are securely fastened and the bolts are tight.

Winch inspection:

• Make sure the cable, strap and line are in working condition. Replace these if they are even slightly damaged.

• Make sure the winch mechanism itself functions properly. Lubricate it as needed and tighten the bolts as required.

Eye Appeal

Wash the trailer when you wash the boat. Apply a coat of wax each year to keep the trailer looking sharp. If you use the trailer in saltwater, wash it thoroughly every time you use the trailer to prevent saltwater-related corrosion issues.

Pre-Trip Checklist

Ranger® Boat’s Rick Huddleston was kind enough to create a custom trailering checklist for us:

• Check the tire inflation pressure (should be 50 to 60 psi for 14-inch tires and 65 psi for 15-inch tires).

• Make sure the hydraulic coupler brake release tab isdisengaged (See your trailer owner’s manual for more detail).

• Check the lug nuts for proper torque (100 ft lbs).

• Use a quality torque wrench.

• Be sure all trailer lights are working correctly before every trip. Turn on flashers and parking lights and do a walk around.

• If the swing tongue has up and down movement, tighten the pivot bolt.

• If the winch stand has movement, tighten the bolts at the main frame and at the joint of the two parts of the winch stand. Check the brake fluid level. Fill to within three-eighths of an inch of the top.

• Know the tow rating of your vehicle. Know the GVWR (Gross Vehicle Weight Rating) of the trailer. (Class 3 hitches are rated up to 5000lbs. Class 4 hitches are rated up to 7000 lbs.)

• Tongue weight should be five to ten percent of the GVWR of the trailer. (Example: 5000 lb. GVWR rated trailer = 250 to 500 lbs of tongue weight).

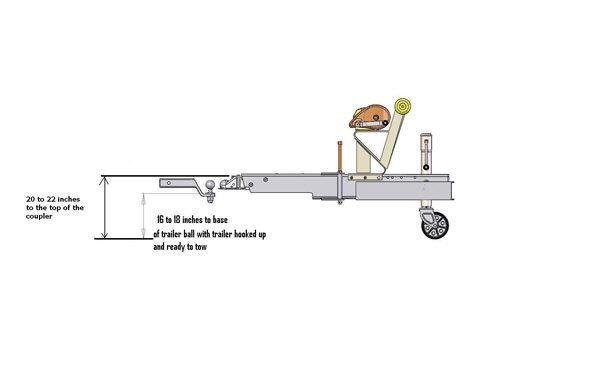

• Hitch height should be 16 to 18 inches from the ground to the base of the trailer ball. (see diagram below)

• Look for leaks – oil, grease, air or brake fluid.

• Make sure to give saltwater trailers a fresh water washing after every use in saltwater.

Finally

Obviously, we’ve only presented the highlights of maintaining a boat trailer. For more in-depth information, refer to the trailer’s owner’s manual or talk to your local marine dealer. It doesn’t matter if your boat trailer is a slick, high-tech boat-toter or an older model – take good care of your trailer and it will take good care of you.

Resources:

Ranger® Boats

870-453-2222, rangerboats.com

Rubber Manufacturing Association

202-682-4800, rma.org

Skeeter® Products, Inc.

903-984-0541, skeeterboats.com

Yamaha Motor Corporation, USA

866-894-1626, yamahaoutboards.com